By Chara Fitch

Penn State student Samuel Highfield holds a red-hot sample of lunar ilmenite after only 30 seconds in an ordinary microwave. Photo: Kate Myers / Penn State.

Penn State student Samuel Highfield holds a red-hot sample of lunar ilmenite after only 30 seconds in an ordinary microwave. Photo: Kate Myers / Penn State.

“We’re an exploration species,” said Sven Bilén, Professor of Engineering Design, Electrical Engineering, and Aerospace Engineering at Penn State. From the first global explorers to the Space Race of the 20th century, human beings have been pushing the limits of what we know and where we can go. The recent push to establish a permanent human presence on the Moon through NASA’s Artemis program has sparked renewed excitement about space exploration and the innovations it requires. We’re feeling that same excitement here in Happy Valley as we develop the innovations necessary for our return to the Moon—this time to stay.

Along with his collaborator, Aleksandra Radlińska, Associate Professor of Civil Engineering, Bilén and his team of students at the Student Space Programs Laboratory (SSPL) are exploring the capabilities of earthly resources to create systems that can sustain a long-term presence on the Moon. “When we look past just visiting, there’s so much work to be done if we want to stay,” Bilén said. “For example, how do we construct infrastructure on the Moon?” The SSPL hopes to answer this question with a high-powered solution based on everyday technology: the common microwave oven.

Forging ahead with NASA collaboration

Recently, NASA’s highly competitive BIG Idea Challenge announced teams that are participating in this year’s theme, “Lunar Forge: Producing Metal Products on the Moon.” Penn State’s SSPL was awarded $130,000 to pursue microwave technology to simplify and enable metal production in a lunar environment—the only one of seven participants taking this route. NASA is funding their SMELT (Smelting with Microwave Energy for Lunar Technologies) System to get them through their research and proof of concept before they pursue other sources of funding. “Most people just interact with microwaves in their kitchen when cooking,” Bilén said, “but there’s so much more potential for using microwaves for all sorts of applications.”

SMELT has the capability to melt down larger quantities of metal ore, in far less time, and—so far—only half the power.

Student lead Patrick Moore noted that their research is “very different from the standard leftover-reheat you usually do at home.” Most documented experiments with microwave smelting are DIY backyard scientists that use a standard commercial kitchen microwave. “For obvious reasons, trying to melt metal this way is not the most efficient, in addition to the fact that these setups are restricted by the small size of off-the-shelf microwave ovens,” said Moore. “SMELT has the capability to melt down larger quantities of metal ore, in far less time, and—so far—only half the power when tested under similar conditions in our early prototyping phase.”

The team is working with samples of ilmenite, a common iron-titanium oxide found both on Earth and on the Moon. When the material meets a souped-up version of the technology found in a household microwave, it begins to smelt. “We do what you shouldn’t do—we take a microwave and we put metal in it,” Bilén said. “Microwaves can get the metal to temperatures where the ilmenite smelts into a molten liquid, which can be used to make components for building permanent structures on the Moon.” Because microwave-based systems are lightweight, easily transportable, and don’t require oxygen or a thermal source for smelting metal, they make a perfect candidate for a lunar forge.

“SMELT is pushing the envelope of smelting into a domain that is currently only used in small-scale backyard forges,” said student lead Alex Baumgartle. “A big focus of our research is bringing this technology to a scale large enough to satisfy the metallurgical needs of a colony on the Moon or another planet. If this technology scales well enough, it should have the advantage of being lighter weight than other smelting methods.”

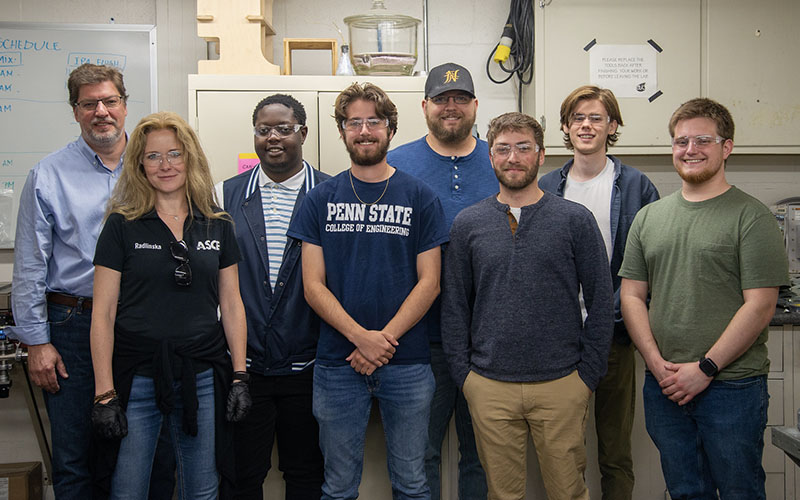

The SSPL works together to push the boundaries of lunar innovation. From left to right: Sven Bilén, director of the Student Space Programs Lab; Aleksandra Radlińska, associate professor of civil engineering; and undergraduate students Craig Oluoch, Samuel Highfield, Alex Baumgartle, Colton Washburn, James Connelley and Patrick Moore.

The SSPL works together to push the boundaries of lunar innovation. From left to right: Sven Bilén, director of the Student Space Programs Lab; Aleksandra Radlińska, associate professor of civil engineering; and undergraduate students Craig Oluoch, Samuel Highfield, Alex Baumgartle, Colton Washburn, James Connelley and Patrick Moore.

Photo: Kate Myers / Penn State.

Creating a sustainable lunar economy

But Bilén believes that their research could just be the beginnings of what he calls a “microwave economy” on the Moon. “High-power microwaves are a resource for more than just smelting. We can use the technology for sintering to make bricks or even extracting water from lunar regolith, and the beautiful thing about newer microwave sources is that they don’t burn out,” Bilén said. He explained that the technology in an average kitchen microwave oven uses a magnetron, a tube-based device invented during World War II, that can burn out when used for high-powered purposes like smelting. With SMELT, the SSPL will employ Solid State Power Amplifiers, or SSPAs—a new technology that is much more durable and efficient.

This is a huge industry, and it’s growing. Happy Valley will play a significant role in future space research.

Recently, Bilén and Radlińska, along with other AddConLab members, were part of another project that started in response to NASA’s 3D-printed Mars Habitat challenge, which won second place at the finals in 2019. Interested in commercializing the state-of-the-art 3D-printed concrete technology that was developed during that project, Bilén and several others founded X-Hab 3D right here in Happy Valley (read more about the project here!). Last year, the company received a DARPA grant to develop 3D-printed artificial reefs and they just landed a contract with NASA to develop lunar concrete cured with microwaves. Bilén sees a clear connection between this research and their new microwave technology—even lunar concrete needs to be reinforced with rebar, which necessitates a smelting method to make it. “There are a number of different research fields that have converged for this smelting project,” Bilén said. “I’ve always enjoyed working at the interfaces of disciplines, focusing on where they intersect because that is where so much innovation happens.”

Radlińska believes that this collaboration with NASA is just the beginning of a new stage of lunar research. “The most exciting part about NASA-funded research is discovery and the structure in place to foster new collaborations and continue research based on findings to date,” she said. “My first NASA project, MICS (Microgravity Investigation of Cement Solidification), led to several new research awards with new collaborators and a growing group of researchers with a common goal of advancing our knowledge.”

Promoting space research in the Brain Belt

Happy Valley is the perfect sphere for this kind of collaboration between commercial, research, and student forces. “We’re situated in the center of the Brain Belt,” Bilén said. “We have a billion-dollar research institution that inspires a lot of innovation and ideas. Penn State’s amazing research capabilities make it the anchor for innovation.” One of the organizations helping to grow the space industry in the Happy Valley region is the Keystone Space Collaborative, a nonprofit organization dedicated to supporting and serving the growing space industry in Pennsylvania, Ohio, and West Virginia. This organization and others are a growing resource that promotes the vital space research being done by universities such as Penn State and helps to bring it into the public and private sectors.

Beyond the rich research environment, the region is known for its forward-thinking, thanks to the 40,000-plus students that live on Penn State’s campus. “Happy Valley is rich in young and powerful minds,” Radlińska said. “They can take us to places we haven’t even thought about yet!”

The most exciting part about NASA-funded research is discovery and the structure in place to foster new collaborations and continue research based on findings to date.

Moore is hoping to go into the field of asteroid and space mining or other forms of astronautical infrastructure development, and he believes this project will pave the way for his career and those of his peers. “Not many universities could offer opportunities like this,” he said. “My hopes are that this project strengthens Penn State’s—and especially SSPL’s—research ties with NASA so that many future students can have the amazing opportunities and experiences we’ve been afforded. We’re looking forward to showing NASA what SSPL and Penn Staters can do to help further the success of the Artemis program.”

Bilén sees massive economic and innovation potential in the space industry and believes it will transform the region: “This is a huge industry, and it’s growing. Happy Valley will play a significant role in future space research.” But the draw of the region isn’t just in its development resources. Bilén loves the State College area for its quality of life that’s hard to find in similar centers of research. “You can experience the flood of ideas and enthusiasm here without the heavy traffic and expensive coffee!”

Radlińska and Bilén examine a smelted sample of ilmenite. Microwave smelting not only has the potential to structure a new world, but it could also be the key to preserving this one. Photo: Kate Myers / Penn State.

Radlińska and Bilén examine a smelted sample of ilmenite. Microwave smelting not only has the potential to structure a new world, but it could also be the key to preserving this one. Photo: Kate Myers / Penn State.

Sustainability potential

The potential for SMELT technology won’t only impact the space industry. Bilén and his students see potential for real-world sustainability applications for microwave smelting technology, like cutting down significantly on the energy used by thermal smelting processes and making it possible to smelt metal using renewable energy sources that often are not available 24/7. Consistent power sources are critical for traditional thermal smelting techniques, but microwaves can use intermittent power sources. Bilén says that he and Radlińska are exploring the use of high-power microwaves within the broader concrete production and curing process, which if feasible will help reduce carbon dioxide emissions associated with concrete production, helping to address climate change concerns with the construction industry.

“NASA is doing research in space, but it’s for space and terrestrial applications,” Radlińska said. “Multiple space-oriented discoveries significantly advanced science on Earth, including climate change observations, air purifiers, baby formula, and memory foam. We all benefit from these inventions every day.”

“People ask, ‘Why should we spend money on going to the Moon, we have problems to address here on Earth!’ But the reality is, when we have big problems that NASA needs to solve and we go through the trouble to solve them, there’s an impact here and we speed up those processes for doing innovative work here on Earth,” Bilén said. “I always look to see where I can have an impact. What can I do that makes an impact in different ways, leaves the world in a better place, inspires the next generation, and uncovers new knowledge?”