What makes Nittany Laser Technologies stand out from its competitors? The fact that there are no competitors — not on this continent, anyway. Drew Nissly’s Philipsburg-based laser welding and cladding company is one of just a handful like it anywhere, and they are solving problems in industries around the world.

The company flies under the radar here in Happy Valley, taking cues from its founder, Drew Nissly. “Quiet and unassuming, Drew might not strike one as the inventor of one of the best ID laser cladding torches on the market. Going head-on against corporations with development budgets dwarfing his own, the success of his products speaks for itself… All companies should be like this,” a client said in a LinkedIn testimonial.

We talked to Nissly about the company’s uniquely-Happy Valley birth, how they are pushing the limits of laser technology, and the benefits of reaching the world from Philipsburg. Read on!

Tell me about Nittany Laser Tech — what’s your secret sauce?

We make custom-designed laser cladding tools and turn-key systems to in-house laser cladding, welding and machining for use in industries like aerospace, mining, marine equipment, rail transport and defense. Our tools are highly specialized. There are only two to three other companies who make similar tools globally, and we are the only one in North America.

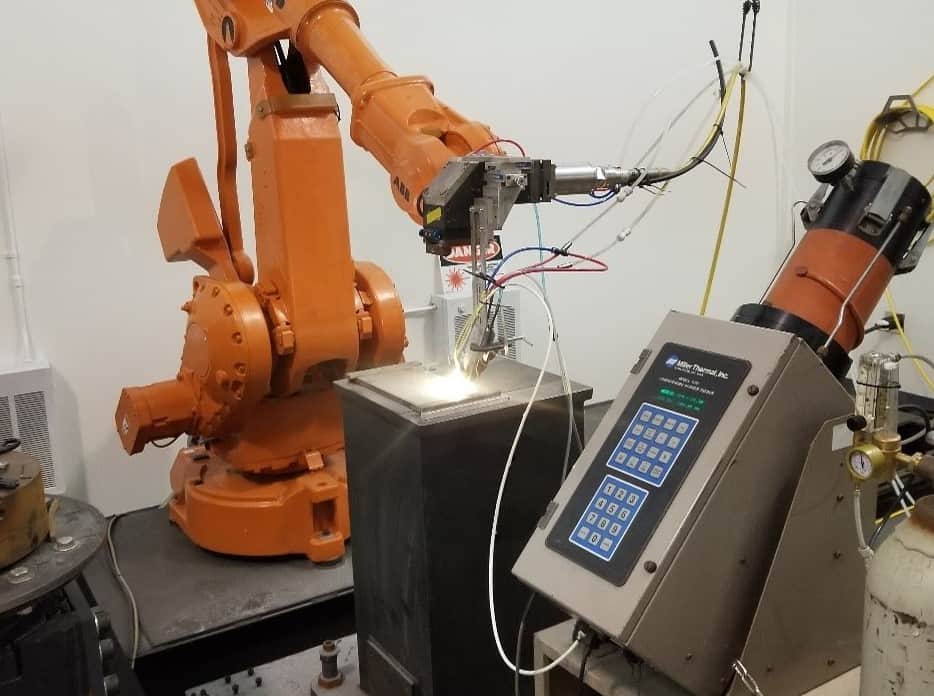

We make machines that do laser welding, which joins two parts together, and laser cladding, which welds metal onto a worn out surface and brings it back to its original dimensions or gives it a very hard/corrosion resistant coating so that the part will last many times longer.

We have the capability to weld parts ranging from under an ounce to 30 ft long and 10 tons.

Tell us how you got started.

I worked at ARL under Ted Reutzel (now director of CIMP-3D), and from there, I developed the predecessor of this current technology. I applied for Navy-sponsored small business research grants, and in 2012, Small Business Innovation Research (SBIR) provided funding for us to start the company. I went through the Ben Franklin TechCelerator bootcamp and had a lot of help from the Small Business Development Center (SBDC). We’re located in Philipsburg in The Moshannon Valley Economic Development Center.

How are you helping your customers succeed?

One of the benefits of laser welding is that it’s very precise with a fifth of the amount of heat of traditional welding, so this has tremendous benefits for the oil and gas industry. We can help them weld inside hard-to-reach places like gears, valve components, drilling bits and engine cylinders. By applying superior coatings to these parts, it saves our customers lots of time and money by greatly reducing failures in their parts…which may be critical parts a mile or so down inside the earth. Lost operating time is very costly to our customers, so parts that last longer are highly valuable.

Laser welding and cladding technology has many advantages over traditional arc welding. There are many materials that we can weld that can’t be welded traditionally. Also the low heat input greatly reduces heat distortion in the part, which is a large problem with arc welding. The coatings that we can put on with the laser have better metallurgical properties. They are harder and more corrosion resistant.

We’ve developed a wide range of laser cladding tools, even a tool for laser welding underwater.

How are you pushing the limits of laser technology?

We are always making our tools smaller and more reliable. Right now we can go inside something that’s 1.5 inches in diameter, so what about an inch? We are working our way down that way. We are continually developing ways to access parts that are smaller or further inside of a pipe.

Why Happy Valley? What are the benefits of existing here in the Happy Valley ecosystem?

It’s been good to have collaboration with PSU and ARL with our customers within the Navy. Philipsburg fits their needs. I live in State College, but it’s a lot more economical to have the company here where the rent is much less than in State College.

Since we have customers from all over the world, our location could be anywhere, but it’s great to have the proximity to State College coupled with the affordability of Philipsburg.

Being in Happy Valley is the best of both worlds: It’s a small town that has lots of diversity because of the university, but without the headaches of a big city.

Cara Aungst writes about industry, innovation, and how Happy Valley ideas change the world. She can be reached with story ideas and comments at Cara@AffinityConnection.com.