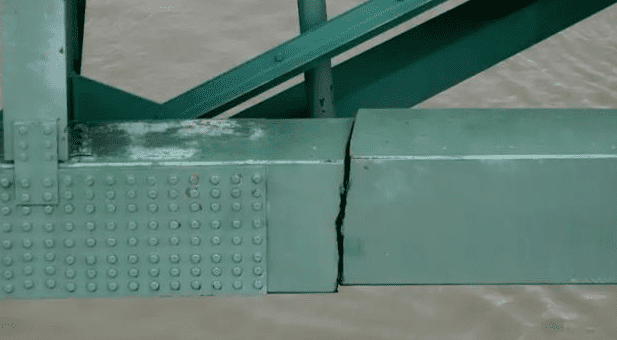

Hernando DeSoto I-40 bridge, Memphis. Image: Josiah Persad

In May, a large crack discovered in a steel I-beam closed the Hernando de Soto I-40 Bridge in Memphis. One of only two major interstates crossing the Mississippi Rivers, its closing is estimated to cost the trucking industry $2.4 million a day in additional transit time. Technology developed by Happy Valley’s TechKnowServ (TKS) is working to detect and accurately size steel bridge fatigue cracks in their earliest stages to prevent similar problems across the country.

TKS has a broad base of 400+ customers in North America and globally that rely on its advanced engineering field services to ensure that their assets continue to operate safely, reliably, and economically.

“If you have had the opportunity to see the I-40 bridge pictures posted on social media or broadcast by the media outlets, the natural question is, ‘how could a competent person miss a crack that size?’” said TKS President Thomas Hay. “Well, that’s a great question and with many human and process variables in play, it will be interesting to see what investigators determine as contributors to the undetected crack. It likely that the crack started out as a stress concentration which intensified under fatigue until fracture occurred. In its early stages, the crack may have been too small, located subsurface, or hidden underneath a coating and undetectable by the human eye. How it grew to its existing size undetected is a totally different question.”

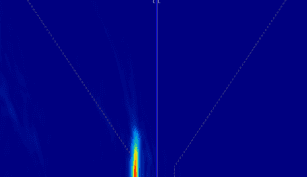

The technology developed by TKS uses ultrasonic waves that are strategically focused to improve the likelihood of crack detection, locate the fatigue crack accurately and most importantly to measure the crack size.

“The core technology has been around for a while, but it’s only recently been packaged into a platform that is suitable for bridge inspection by Olympus (State College, PA) and other suppliers,” Hay said.

The TKS portfolio of bridge inspection projects includes signature bridges across the country, with two recent additions in Missouri and New Jersey. Both projects involve the inspection of bridge girders, similar to Hernando DeSoto I-40 bridge for early-stage fatigue cracks.

“Using the technology, the TKS inspection team located multiple cracks that were unobservable to the human eye and other standard inspection techniques,” Hay said. “The crack propagated vertically into the steel girder though approximately 10% of the plate thickness. The crack was repaired immediately to prevent further crack growth, to restore the bridge girder to its designed load rating and continued safe operation of the bridge.”

Other recent projects for TKS include an engineering assessment of pressure vessels used to deliver mixtures of oxygen, helium, and nitrogen gas to dive teams welding oil and gas infrastructure on the bottom of the Gulf of Mexico; streamlining regulatory compliance using on-line sensing technology for the world’s largest semiconductor foundries; and advanced non-destructive testing services that identify structural integrity issues for port authorities, state departments-of-transportation, and hydropower and navigation infrastructure operated by the U.S. Army Corps of Engineers.

Learn more about TechKnowServ: techknowserv.com.