By Jeff Cavanaugh

Dr. Amir Sheikhi and his team are working to address nationwide organ transplant shortage at Shekhi Lab at Penn State University. Photo: Penn State.

Penn State researchers have developed a potentially groundbreaking solution to the nationwide organ transplant shortage, using a new class of bioinks that produces engineered live tissue using 3D printing technology.

The team of researchers, led by Dr. Amir Sheikhi, Penn State assistant professor of chemical engineering, set out to overcome the long-lasting structural limitations of current bioinks and, as a result, developed a new class of bioinks, made up of small-scale, tissue-like compartments that can be assembled to each other in such a way that the void spaces remain available for cells to occupy.

“Penn State has provided a supportive atmosphere to leverage my research in the past three years. The lab space, startup funds, research support as seed grants, summer funds for undergraduates and accessible shared facilities are all among the numerous support that I have received from Penn State.”

“To make synthetic organs, cells need to be placed in materials that mimic the environment in the body. In this research, we developed a new class of materials that can be 3D printed into complex forms and readily enables cells to reside, move around, communicate and make tissue-like constructs,” Sheikhi explained. “Ultimately, we want to address the organ shortage, which is a global challenge in the current century.”

Organ donation and transplantation remain the best and most cost-effective clinical solution for many patients experiencing organ failure. However, according to the Health Resources and Services Administration, there are over 105,000 people on the national transplant waiting list – and of those, 17 people die each day while waiting for a transplant.

New bioink overcomes previous limitations

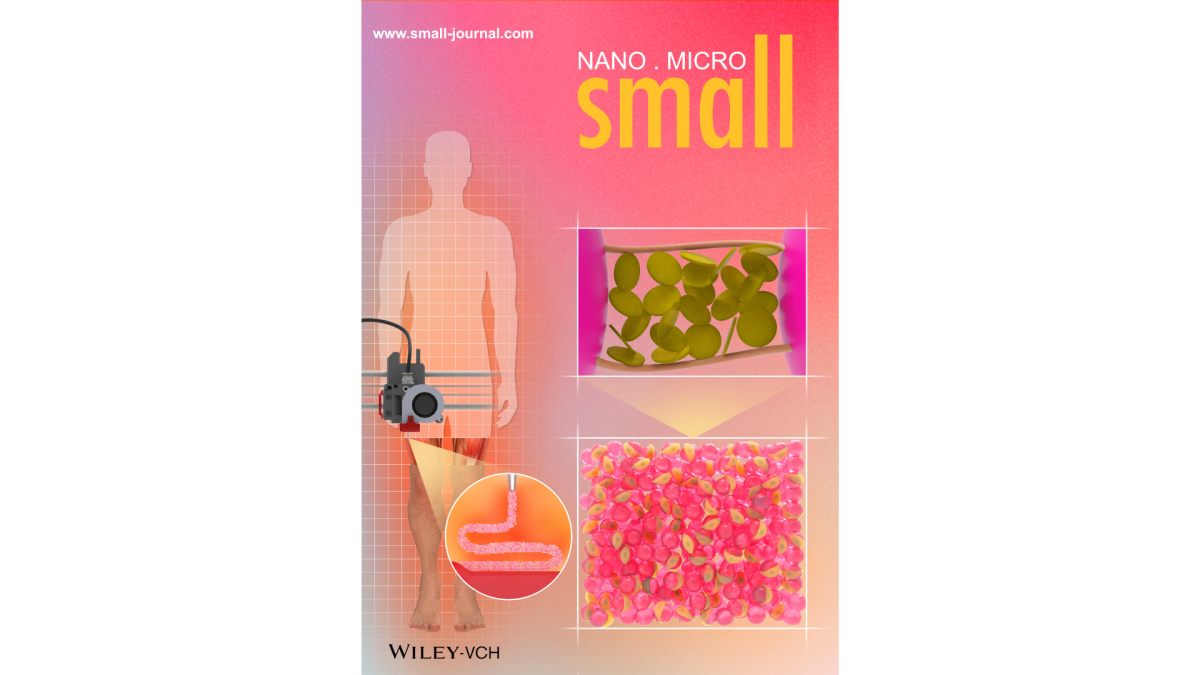

The team of Penn State researchers’ novel, nanoengineered, granular hydrogel bioink makes use of self-assembling nanoparticles and hydrogel microparticles, or microgels, to achieve previously unattained levels of porosity, shape fidelity and cell integration.

“I sincerely hope that the technologies that are being developed in our lab can someday save humans’ lives and protect our endangered ecosystems.”

To date, the majority of bioinks have been based on bulk hydrogels — polymer networks that can hold a large amount of water while maintaining their structure — with nanoscale pores that limit cell-cell and cell-matrix interactions as well as oxygen and nutrient transfer. They also require degradation and/or remodeling to allow cell infiltration and migration, delaying or inhibiting bioink-tissue integration. Sheikhi noted that one of the biggest challenges of 3D bioprinting is developing a material that has both mechanical robustness – like tissue – that, at the same time, is injectable and has cell-size pores that can accommodate cells.

The team overcame these previous limitations of 3D bioprinting granular hydrogels by reversibly binding the microgels using nanoparticles that self-assemble. This enables the fabrication of granular hydrogel bioink with well-preserved microporosity, enhanced printability and shape fidelity

“We address all these challenges by combining nanotechnology and microengineering techniques that we established at Sheikhi lab,” Sheikhi said. “The work would not be possible without the amazing efforts of graduate and undergraduate students. The next step will involve expanding this technology to several tissues and trying to fabricate synthetic tissues in the lab.”

The work of Penn State researchers to develop a new class of bioinks to make tissue for synthetic organs recently appeared on the cover of Small, a weekly, peer-reviewed scientific journal. Photo: Provided.

Sheikhi Lab leading health care innovation in Happy Valley

For this research, Dr. Sheikhi was named a “Rising Star” by Small, an academic journal that focuses on nano- and microscale science. The Rising Star series is intended to “celebrate the diversity of the international scientific communities that [the journals Advanced Science, Advanced Materials, Advanced Healthcare Materials and Small] serve by collecting outstanding research articles on studies conceptualized and supervised by recognized early career researchers from around the world,” according to the journal’s website.

“I am honored to be recognized as a Rising Star by the journal, one of leading journals in the field of materials research. This indeed recognizes not just me, but the whole Sheikhi Lab and their contributions to developing new materials that can solve real-life health care problems,” Sheikhi said. “I sincerely hope that the technologies that are being developed in our lab can someday save humans’ lives and protect our endangered ecosystems.”

Sheikhi Lab is the academic home of more than 25 researchers from 10 different countries, all focusing on finding solutions to some of the biggest challenges to humans and ecosystems. The lab comprises approximately 1,300 square feet of space located on the fourth floor of the new Chemical and Biomedical Engineering Building at Penn State.

“Penn State has provided a supportive atmosphere to leverage my research in the past three years. The lab space, startup funds, research support as seed grants, summer funds for undergraduates and accessible shared facilities are all among the numerous support that I have received from Penn State,” Sheikhi added. “I am greatly thankful to Penn State, all the mentors and my trainees who have contributed to our research.”

The other authors of the paper published in Small are chemical engineering doctoral students Zaman Ataie and Sina Kheirabadi; chemical engineering undergraduate students Rhea Jiang and Carter Petrosky; mechanical engineering and biomedical engineering undergraduate student Christian Vollberg; mechanical engineering undergraduate student Jenna Wanjing Zhang; and biomedical engineering undergraduate student Alexander Kedzierski.

“Ultimately, we want to address the organ shortage, which is a global challenge in the current century.”

“Challenges that humans are facing cannot be solved by one person or one lab, and a more holistic approach to addressing our needs is required,” Sheikhi added. “My lab always welcomes collaborators, visitors and investors to help further health care and disease prevention technologies.”

For more information on the research being done by Dr. Amir Sheikhi and his team at Penn State University, visit www.sheikhilab.com.