By Timothy Kelly

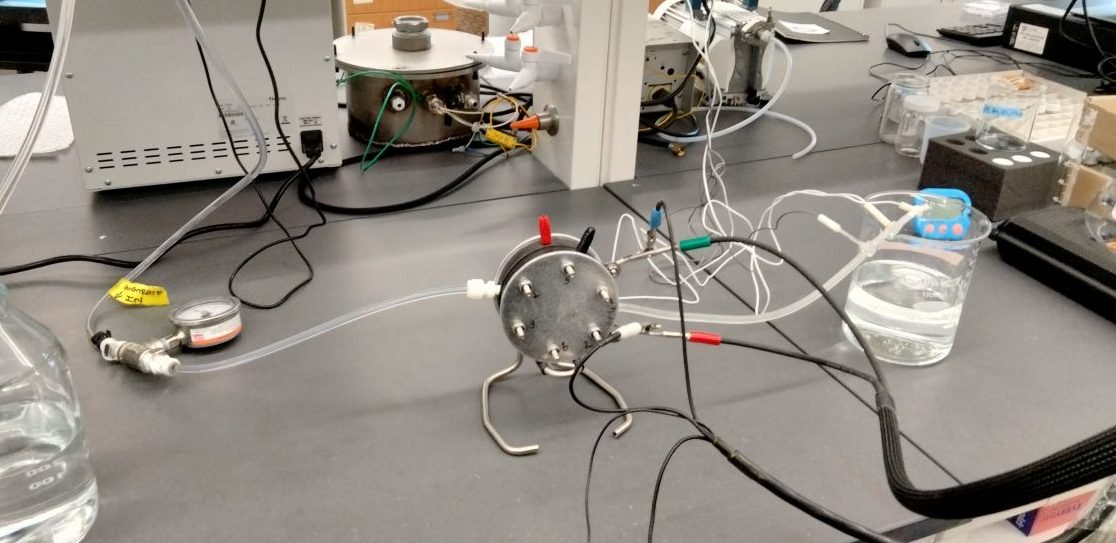

An experimental MCDI unit. Photo: Chris Arges.

A team of researchers, led by Chris Arges, Penn State associate professor of chemical engineering, is working to optimize a water desalination process called membrane capacitive deionization (MCDI) for mobile teams of U.S. Marines. We asked Arges to explain how the system works, why he chose Penn State for his research and why this work is so important. Here’s what we learned.

“The biggest draw to come to Penn State was the nanofabrication facility within the Materials Research Institute.”

How MCDI works

Arges described the MCDI system like a sandwich. The two slices of bread are the electrodes. Two slices of cheese are the membranes stuck to each piece of bread. The bottom membrane only allows sodium to move through it and the top membrane only allows chloride to move through it. The water to be purified moves between the two membranes. When the electrodes are charged, the sodium and chloride move out of the water, into the membranes. The charge holds the ions to the electrodes, thus purifying the water. Purified water is collected in a container.

When the electrodes can’t hold anymore ions, the flow of water is slowed, the charge is reversed and the ions move back into the water, making it briny. The briny water is then routed to waste. As a bonus, this step generates electricity that can be stored for use in the next deionization cycle.

Making MCDI better

Arges said that his team wants to redesign the system so it can operate with more electric current flowing through the material. Pushing more current through the system purifies more water.

Increasing the surface area of the electrodes with microscopic wells allows them to hold more ions. It also increases the contact between the electrodes and the membranes, shortening the distance the ions need to travel.

“The MCDI … units could be found in homes or neighborhoods for purifying water or deployed in emergency areas, like after a hurricane, for producing potable water.”

Arges further explained that the objective is to, “reduce all the resistances… [of] the bulk material [and] the interfacial resistances to a point that gets us the high current without too high of a voltage. That’s… what’s really driving our research in this project.”

He continued, “By studying these interfaces and identifying the bottleneck resistance, we devise strategies to overcome the resistances. This leads to greater ion removal rates from the water during desalination.”

The Materials Research Institute housing the Nanofabrication Lab. Photo: T. Kelly.

Why Penn State?

“When starting my own independent career in 2016 at [Louisiana State University], I decided to apply my expertise in materials for fuel cells to water purification,” Arges said. But something was missing at LSU.

He said the biggest draw to come to Penn State was the nanofabrication facility within the Materials Research Institute. With tools in the Nanofabrication Lab, he said, “we use advanced metrology and fabrication techniques … to study the rate of ion transport and gas/liquid transport … at the nanoscale.”

MCDI solves smaller-scale problems, too

“It is important that we continue to improve the performance and durability of water purification units so everyone, whether rich or poor, has access to quality and potable water.”

Clean water and energy efficiency are in the DNA of Arges’s research, according to the Arges Research Lab website. As to why it’s so important to him, Arges said the water shortages around the world, which are being made worse by climate disruption, moved him to address the problem. He said, “Water is central to our way of life. It is needed for energy production, agriculture … and surviving. It is important that we continue to improve the performance and durability of water purification units so everyone, whether rich or poor, has access to quality and potable water.”

According to Arges, “By improving the materials and their interfaces in MCDI … we hope that there will be greater proliferation of these systems … since they are modular and only require electricity for water purification…” The end result could be a smaller unit with a lower capital cost for purifying water and reduced energy duty.

Even so, the MCDI system won’t solve the large-scale water problems we see around the world, including the American Southwest. Economy-of-scale makes reverse osmosis the most cost-effective solution for large, centralized desalination facilities. By contrast, “The MCDI … units could be found in homes or neighborhoods for purifying water or deployed in emergency areas, like after a hurricane, for producing potable water,” Arges said.