Founded in 2009 in State College to provide testing and consulting services to the power industry, MP Machinery and Testing, LLC (MPM) has grown into a high-technology company that offers a wide range of experimental, analytical and consulting services to various industries. MPM offers materials testing products, test machines and analytical services to industry and government, and performs several specialized services for the nuclear industry, such as radioactive material testing, neutron transport analysis and in-service component failure analysis.

“MPM is considered a technological world leader in impact testing, miniaturized specimen technology, and test machine development,” Dr. Michael P. Manahan, president at MP Machinery and Testing, said. “The breadth and depth of MPM experience is brought to bear on the difficult and challenging problems clients present. It is often the case that a technical approach in one application can be adapted to another, and MPM leverages its extensive problem-solving experience.”

“Compared to other test labs with two to four-week delivery times, MPM has become the lab of choice for many customers.”

Dr. Manahan’s MIT PhD thesis in 1982 launched the field of miniaturized specimen technology. That original application was focused on development of a mechanical property test using 3 mm-diameter TEM disks as part of the national fusion alloy development program. Since then, MPM has developed miniaturized tensile, Charpy and fracture toughness tests for various applications, including cutting small samples from in-service structures to measure the effects of aging and degradation. More recent applications have been found in the additive manufacturing field and in the powder metallurgy industry.

“MPM uses its streamlined machining capabilities to shorten testing turnaround times to less than two days. In a typical case, material arrives late-morning and MPM will have specimens made and tested the same day or next-day, with a certified test report to the customer within two days after receipt of order,” Manahan added. “Compared to other test labs with two to four-week delivery times, MPM has become the lab of choice for many customers.”

Manahan indicated that some MPM clients require quality control testing and they cannot afford to put their production line on hold for over two weeks. The MPM one to two-day test report delivery is essential to these customers to keep their operation going and meet their production schedules.

“And while many of the impact tests done are industry-specific, there are some tests that are even impacting consumer experience. For example, MPM offers impact testing for the beverage can industry that aids in the development of new can designs, the development of new can materials and quality assurance in production.”

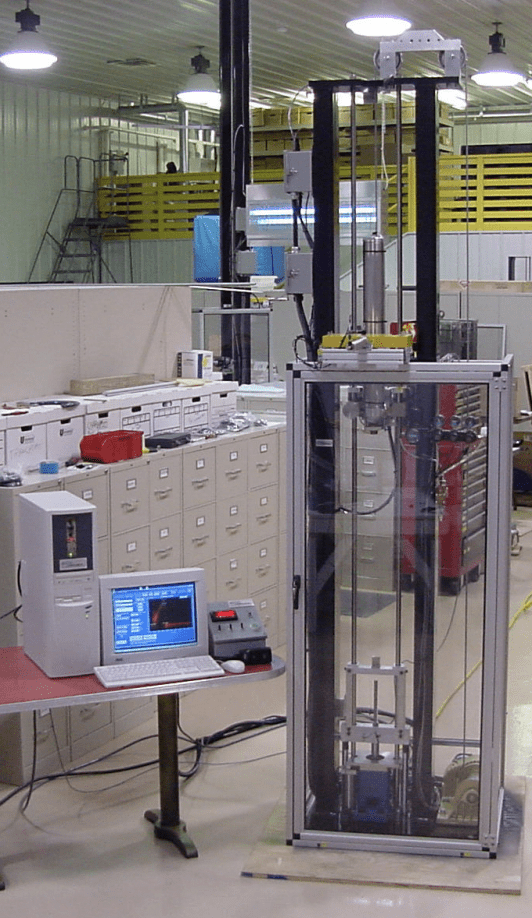

MPM manufactures Charpy impact test machines, instrumented impact test equipment, drop tower test equipment, in-situ heating and cooling equipment, shock testing equipment, multipurpose corrosion cells, high temperature reference electrodes and pressure vessels. It offers services in the areas of material characterization, mechanical property measurement, failure analysis, corrosion testing, in-service component monitoring and finite element analysis.

MPM also has an extensive in-house, precision machining capability and the company continues to offer machining and fabrication services to local businesses and Penn State University.

And while many of the impact tests done are industry-specific, there are some tests that are even impacting consumer experience. For example, MPM offers impact testing for the beverage can industry that aids in the development of new can designs, the development of new can materials and quality assurance in production.

“MPM has adopted the phrase ‘serving client needs through advanced technology’ as its corporate motto,” Dr. Manahan added. “This thought expresses MPM’s focus on customer problems and the highly innovative spirit reflected in MPM problem-solving.”

The results and growth of the services and products offered by MP Machinery and Testing since 2009 has made the State College-based company an industry leader in technology, but the mission remains problem-solving and customer satisfaction.

“MPM has adopted the phrase ‘serving client needs through advanced technology’ as its corporate motto,” Dr. Manahan added. “This thought expresses MPM’s focus on customer problems and the highly innovative spirit reflected in MPM problem-solving.”

For more information about the products and services offered by MP Machinery and Testing, visit www.mpmachineryandtesting.com.