By Carmen P. Bilén

Sensors make many aspects of modern daily life possible.

You begin your morning by checking the calendar on your smartphone to find the day’s appointments. The phone’s touchscreen is a capacitive sensor that uses materials like indium-tin oxide to respond to the touch of your finger.

You realize you have a check-up at the doctor’s today. You get into your car and back down the driveway, when suddenly you hear a loud beep alerting you that a dog that has run ahead of its owner and into the path of your car. That alert was possible due to ultrasonic sensors located on your car’s fender.

When you arrive at the doctor’s office, the sonographer uses ultrasound equipment to check the progress of a pregnancy or to locate a suspicious mass.

Broadly speaking, a sensor, also called a transducer, responds to inputs from the physical environment — such as pressure, temperature or light — and converts these inputs into electrical signals that can be used by a system to provide useful information, either on its own or in combination with other sensors. Modern sensors rely on advanced materials at their heart, such as piezoelectric sensors, which use piezoelectric crystals or ceramics to generate electric signals. When the doctor applies the ultrasonic wand to your body, it sends out a signal and then measures the reflection — similar to a radar, but with sound.

“Materials Valley”

The Pennsylvania Alleghenies is home to many companies that produce, utilize and integrate materials-related sensors for a variety of industries, including oil and gas, steel production, non-destructive measurement and medical technology. In fact, there is such a concentration of materials-related research in Happy Valley specifically that it has been referred to as “Materials Valley.”

Why is this area a hot spot for this type of work?

The biggest reason is proximity to Penn State University Park, with its wealth of experienced faculty, researchers and research facilities. Penn State is the No. 1-ranked materials science and No. 2-ranked materials engineering institution in the country. The Department of Materials Science and Engineering (MatSE) in the College of Earth and Mineral Sciences, for example, is an international leader in materials education and research. MatSE faculty and students conduct groundbreaking materials research through the department’s centers and labs, including the Materials Research Institute’s Center for Dielectrics and Piezoelectrics, a joint venture between Penn State and North Carolina State University.

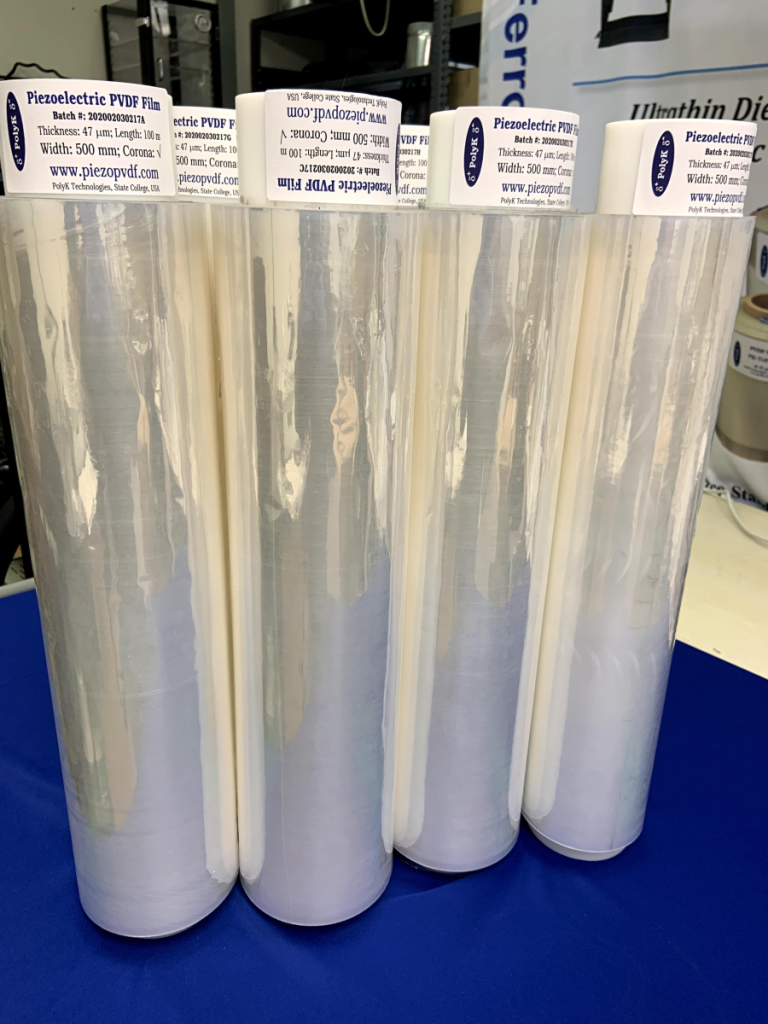

One sensor materials company that has its roots in Penn State’s materials research facilities is Philipsburg-based PolyK Technologies, which makes specialty piezoelectric films for piezo sensor companies both locally and around the world and provides consulting and integration services for their products.

“The density of [these] companies is very high… it’s a very strong ecosystem of companies with specialization in ultrasound technology, from materials to components like transducers.”

The company was founded by Shihai Zhang, a Penn State MatSE alumnus who got his Ph.D. in polymer sciences in 2003. PolyK Technologies has grown since its founding to encompass 40,000 square feet of research and development space in both State College and Philipsburg and now has 13 employees. PolyK Technologies’ piezo materials serve a variety of markets including ultrasonic analysis, bioinformatics, non-destructive testing, traffic monitoring and security.

Piezoelectric sensors are also a key component of ultrasonic testing technology such as that used by TechKnowServ, a State College-based company whose president, Thomas Hay, received his Ph.D. in engineering mechanics from Penn State’s College of Engineering. TechKnowServ (TKS) provides advanced and conventional non-destructive testing services and expertise in acoustic emission testing, phased array ultrasonic testing (PAUT), guided wave ultrasonic testing (GWUT) and magnetic flux leakage (MFL). Ultrasonic sensing technology has many real-world applications for the oil and gas, transportation, steel and medical technology industries.

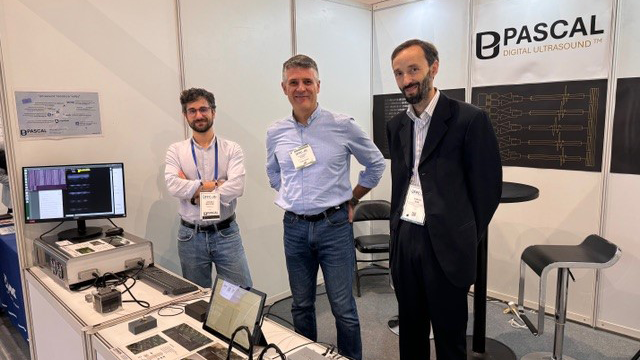

Ultrasound sensing technology is the core business for Pascal Ultrasound, an Innovation Park-based company founded in January 2024 — albeit with a little different focus. Pascal Ultrasound doesn’t produce the sensors themselves but rather provides ultrasound system integration solutions to help other businesses — mainly early-stage companies — to pull together the components that they need to make ultrasound transducers work.

“Ultrasound is normally used to generate medical images with ultrasound and, in those systems, ultrasound is used to extract information from the body and transform it to an anatomical image,” explains Alessandro Gubbini, founder and president of Pascal Ultrasound, “and then that process can be applied to industrial applications like nondestructive testing, so in all cases that equipment needs to generate ultrasonic waves and it does that using dedicated electronic circuits connected to transducers that emit ultrasound.”

“The Pennsylvania Alleghenies, with Penn State as a strong engine for the research and exploitation of novel materials, and a local ecosystem ready to commercialize those materials into sensors, will be at the forefront of the future.”

“What I’ve found through my experience in the industry, especially the last few years as a consultant, was that suppliers of all these components are fragmented,” Gubbini continues. “Companies need to source these components from different vendors, so that’s where the system integration component comes in… there aren’t that many companies that do integration.”

He added, “With Pascal, I’m integrating all the components that go into ultrasound-based products – electronics, transducers [and] connections between the two.”

Strong local ecosystem

Gubbini, who has worked in the region for more than 20 years and also has a consulting business called Soundflair LLC in addition to Pascal Ultrasound, has deep connections with materials research at Penn State, with local entrepreneurs through the Startup Leadership Network and Invent Penn State, and with local sensor companies including Sound Technology, Inc. (now part of GE), where he used to work. He says one of the best things about being located in the region is the “local ecosystem of ultrasound” that exists here.

“Actually, in State College or in general Happy Valley, I call it ‘Ultrasound Transducer Valley’ because there are many companies that deal with these types of components, especially transducers”, says Gubbini. “The density of [these] companies is very high… it’s a very strong ecosystem of companies with specialization in ultrasound technology, from materials to components like transducers.”

One thing is clear: Our modern lives will require new and innovative sensor technologies to push forward all kinds of consumer devices and industrial technologies. And those new sensors will require novel materials and manufacturing methods. The Pennsylvania Alleghenies, with Penn State as a strong engine for the research and exploitation of novel materials, and a local ecosystem ready to commercialize those materials into sensors, will be at the forefront of the future.

Carmen Bilén is a freelance writer and associate director of Engineering Career Resources & Employer Relations at Penn State. She can be reached at cpb10@psu.edu.