By Cara Aungst

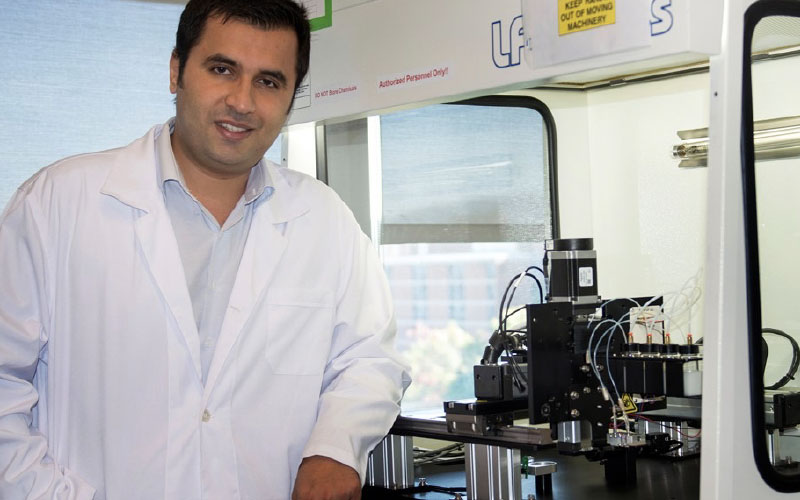

Ibrahim Ozbolat leads a lab specializing in 3D printing to create a range of tissues for use in human health. Photo submitted.

Ibrahim Ozbolat leads a lab specializing in 3D printing to create a range of tissues for use in human health. Photo submitted.

Penn State is leading the way in a new endeavor to 3D-print human tissue and bone at scale. When fully developed, the technology will be the first to enable the fabrication of scalable, native tissues with high cell density such as bones, tracheas and organs. The project recently saw a major milestone as it moves toward translation: the National Institute of Biomedical Imaging and Bioengineering at the National Institute of Health has awarded over $2 million in support of the project.

It’s the second time that the team, led by Ibrahim T. Ozbolat, professor of engineering science and mechanics, biomedical engineering, and neurosurgery, has received federal funding on the technology. In 2019, NSF awarded funding to explore the fundamentals of the technique. Today, NIH funds will be used to scale up the process and quickly bioprint spheroids into desired patterns for the fabrication of tissues with cell densities similar to what is found in nature.

We sat down with Dr. Ozbolat about his groundbreaking research and how Penn State’s collaboration and research prowess made it possible.

Can you tell me a little bit about your research and why it’s so important for the future of healthcare?

My research is in the field of 3D printing of living tissues and organs, so we built tissues and organs. Ultimately, these organs will replace the damaged organs, which will save lives and improve the quality of life for patients.

We print more than 12 different tissues — from cartilage, bone and skin to more solid organs like lungs. Some of these tissues are not developed to scale but they recapitulate the physiology of the native tissue. We can test drugs or explore the development of diseases and build up some therapeutics before the treatments are translated into clinics and tested on humans.

I was imagining a lab where I could do 3D bioprinting and do the implantation or transplantation work right away, in the same lab. I visited the Huck Institutes facilities and particularly the Millennium Science Complex building and I said, “Oh, my God.” I loved the feeling I had in that building.

Can you talk about the actual substance that’s being printed?

The actual substance is cells like living cells from humans, obtained with biopsies or stem cells differentiated into different cell types that can be used for building different tissues. We can start with a stem cell and we can make bone tissue from the stem cells, and then we can implant that bone tissue into a patient. These cells can be printed in three-dimensional hydrogels — jelly structures that your cells grow in — or they can be printed in aggregates in what we call spheroids. These spheroids assemble and make a larger-scale tissue. You can also start with high-density cells like in a spheroid and put them next to each other and they self-assemble and make a larger-scale tissue. Wow! The grant that we received from NIH was related to this spheroid model.

What else is your team working on, in addition to the grant?

Apart from the grant, we’ve been doing various different things. We made substantial progress with bone tissue regeneration with the bioprinting technology, and we expect some of those to be going toward clinics.

In the meantime, we are developing bioprinter technologies as well. We are not just making the tissue, but we are also developing the technology that makes the tissue. We’ve already developed various technologies like coaxial bioprinting, that are in the market already and have been adopted by labs and companies.

What inspired you to pursue this research?

I’ve been in the field for a long time … 16 years. I started my research with 3D printing and was exposed to tissue engineering when I started my PhD. I could see that there was a lot of potential because of the possibility of printing replacement body parts. I knew that the ultimate goal was to build organs. I had 3D printing skills, so I thought, why don’t I apply that to the field of tissue engineering, instead of building inert materials like metals or plastics? We can just print cells and make tissues.

What brought you to Penn State?

I was an assistant professor at the University of Iowa before I came to Penn State. At UI, the medical school and engineering schools were close, but the support was very, very limited. I was imagining a lab where I could do 3D bioprinting and have my lab do the implantation or transplantation work right away, in the same lab.

During my Penn State interview, I visited the Huck Institutes facilities and particularly the Millennium Science Complex building and I said, “Oh, my God.” I loved the feeling I had in that building.

They gave me an offer that included space in the Millennium Science Complex building. Now we build tissues, have an animal facility and core facilities for pretty much anything — it’s all in a single building. That’s freedom. When you add in creativity, that’s the recipe for success.